How to make Nembutal at home

With the drug becoming very hard to get, learning how to make Nembutal at home is now the most talked about topic. We have decided to put out information on how you can make your own Nembutal at home using simple equipment. This post contains a step by step guide and everything has been explained so that even an 8 grader can understand.

The ongoing difficulties in obtaining the best euthanasia drug, Nembutal, saw Peaceful Pill Directory become involved in an ambitious research project – the synthesis of one’s own ‘Peaceful Pill’.

The Peaceful Pill Project ran for several years involving a diversity of our members. Many strategies were explored (and rejected) with some significant advances made. In this Chapter we detail this research and discuss in more detail the use of the drug Nembutal for a peaceful death.

If you cannot make it at home then simply send us an email and we will send you the list of vendors so you can order Nembutal online.

Making Nembutal

Making Nembutal involves the acquisition of restricted and hard-to-get chemicals and the use of processes that are difficult and occasionally dangerous for a novice.

Nevertheless, as the pathways become established and simplified, safer processes are developed and recorded. An outline of the steps required for barbiturate synthesis and assay are described and illustrated where possible with video.

First Time making Nembutal at home

The first time we tried making Nembutal Peaceful Pill was in 2004. – We called it the ‘Nicky Finn’ the famous Micky Finn drink of the Lone Star Saloon in Chicago in the early 1900s. The Peaceful Pill was made from alcohol and nicotine.

In this process, the Peaceful Pill was Manufactured by chlorinating alcohol and combining this chloral hydrate with pure nicotine. The final product was highly effective and highly lethal when taken as a drink.

Although synthesis was straightforward, the difficulty in testing this untried product left questions about this strategy unanswered.

Changing Focus

In 2005 a group of intrepid Voluntary Euthanasia and Assisted dying advocates launched the ‘Peanut Project’. Named after an old-fashioned street term for barbiturate (Peanuts), the Peanut Project brought together a group of elderly people to create their own barbiturate(Nembutal).

Could they make Nembutal?

How could they make something that:

- they could take orally

- could be manufactured without outside assistance

- would provide a peaceful and dignified death

- would be reliable with negligible risk of failure.

The first Workshop was held at the remote country property of former Australian Attorney General, Kep Enderby QC. The average age of participants was 80 years, although some were in their 90s. Several who participated were seriously ill.

Legal Issues involved in making Nembutal

Setting out to manufacture one’s own Nembutal exposes those involved to significant legal risk with jail and fines of up to half a million dollars. In most western countries there are myriad laws that make it an offence to manufacture, possess, sell, supply and import certain narcotic and psychotropic drugs.

Penalties depend upon the amount of the drug involved, but usually range from two years jail and a fine, to life imprisonment.

In the Peanut Project, there was another additional legal question.

If one member of the group ever died using the substance the group had collectively made, would the remaining members be guilty of having assisted with that person’s suicide?

It was stated clearly at the start, that no one in the initial group would make more than they needed for themselves. No one was making a Pill for someone else, and no one would sell any of the substance manufactured. Finally, no one would acquire more than 10gm of the manufactured barbiturate (the common lethal dose). Any excess would be destroyed.

The Chemistry

How to make Nembutal at Home: The Chemistry involved.

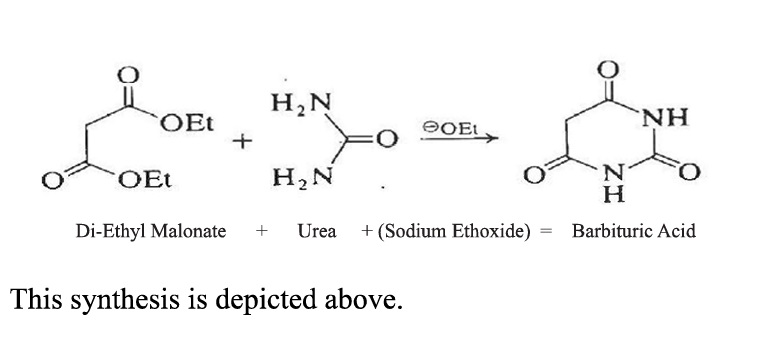

The processes used for making Nembutal and other barbiturates have been known for many years. Barbiturates are derivatives of barbituric acid. This was first synthesized by Adolph von Bayer in 1864, by condensing malonic acid with urea.

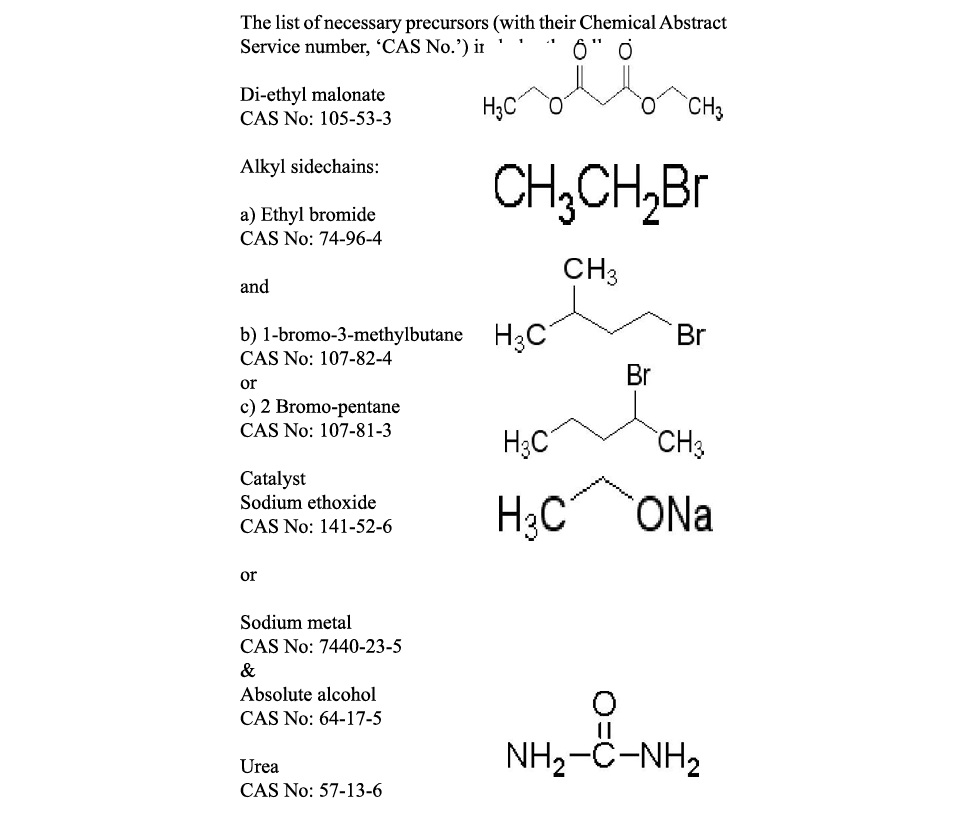

An easier method makes use of the di-ethyl ester of malonic acid (di-ethyl malonate) which reacts with urea in the presence of a catalyst sodium ethoxide; a base is formed by dissolving metallic sodium in absolute alcohol (ethanol).

The reaction takes place under reflux for a number of hours at 110°C. Crystals of barbituric acid are obtained by acidifying the reaction mixture, then filtering and cooling the filtrate. Barbituric acid, however, has no physiological activity. The process needs to be taken further to develop a barbiturate that can peacefully end life. The sedative, hypnotic, and anaesthetic properties of the barbiturates are determined by the characteristics of two additional side-arms (or side-chains) attached to the barbituric acid molecule.

The di-substituted barbiturates of particular interest are amylobarbital (Amytal) and pentobarbital (Nembutal). The process of adding side-arms (di-substitution) needs to be undertaken before the condensation of the malonate and urea.

In Amytal, the two alkyl side arms are (a) ethyl, introduced as ethyl-bromide and (b) 3-methylbutyl, introduced as 1-bromo-3-methylbutane. In Nembutal, the two alkyl side-arms are (a) ethyl, introduced as ethyl-bromide and (b) 1-methylbutyl, produced from 2-bromopentane. In both substitution reactions the malonate is heated, either in a closed pressure system (autoclave) or under reflux first with one and then the second alkyl bromide. In both reactions sodium ethoxide is used as the catalyst.

The final step in the production of sodium pentobarbital or sodium amylobarbital is heating of the resultant di-substituted malonate with dry urea in an autoclave or under reflux for another 12 hours. This is again done in the presence of dry alcohol and sodium. Excess alcohol is removed by distillation and the residue – predominantly sodium pentobarbital, or sodium amylobarbital – is dissolved in water to form the Peaceful Pill.

In all of the di-substitution reactions and in the condensation with urea, it is essential that there be absolutely no water present.

Care must be taken to ensure no atmospheric moisture reaches the autoclave or reactor vessel. All substances used must be dry.

In particular, the alcohol used in the production of the sodium ethoxide needs to be as dry as possible (super dry).

Equipment

In the original project, the period of prolonged reflux was carried out using a two-litre glass reaction vessel with three Quickfit taper necks (24/29), fitted with an efficient double surface condenser (Fig 20.1). A heating mantle and a means of stirring the mixture and monitoring the temperature were also required.

To protect the reacting substances from atmospheric moisture, calcium chloride guard tubes were used. To remove excess alcohol in the final stage, the double-surface condenser was attached to the reactor vessel by means of a distillation head.

The alcohol that was distilled was collected in a glass receiving vessel that was also fitted with a calcium chloride guard tube (Fig 20.4). An accurate chemical balance, capable of measuring to 0.1g, was required to weigh out the necessary reactants.

In the subsequent ‘Single Shot’ project, a specialised stainless steel pressurised reaction vessel (autoclave) was employed. This replaced the glassware and the reflux condenser. This sealed stainless steel vessel (autoclave) allowed the reaction to take place under pressure, shortened reaction time and reduced the problem of contamination from atmospheric moisture (Fig 20.2).

Pressure was read directly from the gauge with the temperature in the reaction vessel read via a thermocouple (with an infrared thermometer used as backup).

To remove the substituted malonates from the reaction vessel a condenser was employed. This was made from stainless steel tubing surrounded by a water jacket. Connected to a receiving vessel of stainless steel this was then vented using a calcium chloride guard tube and placed under reduced pressure in the distillation process using a water tap vacuum attachment.

The setup of the glassware for reflux used is shown in Fig 20.1.

Note: the presence of the guard tube on the top of the reflux condenser. The distillation setup is shown in Fig 20.3.

The single shot equipment is shown in Fig 20.2. The distillation set-up shown in Fig 20.3

Special Dangers involved in making Nembutal at home

As with all chemical processes, care and attention to detail was needed at all times. The equipment was clean and dry before use.

Many of the liquids used in the synthesis were flammable and naked flames were not used. Heating of the reaction vessel was by way of an electric hotplate. The most dangerous substances used in the process were metallic sodium and the strongly basic intermediary sodium ethoxide. Standard organic chemistry texts (eg. Solomons & Fryhle, 2004) spell out the dangers of handling these substances.

CAUTION: Sodium must be handled with great care and under no circumstances should the metal be allowed to come into contact with water as an explosion and fire may result. Sodium is stored under paraffin or xylene and should only be handled with tongs or tweezers, not with fingers.

Small waste or scrap pieces of sodium can be disposed of by placing them in a bottle containing large quantities of methylated spirits.

The commercial sodium is covered with a non-metallic crust.

A sodium press can be constructed to remove this and produce clean sodium wire for the reaction vessel. See ‘Betty cooks with Sodium’).

None of the chemicals required are subject to specific government restriction. Application to a reputable chemical supplier for ethyl malonate and the chosen side-chain alkyl bromides is generally successful provided one can detail a legitimate purpose in the required end-user statement. Some endeavour may be required to obtain the sodium metal and dry ethyl alcohol. Alternatively, the catalyst sodium ethoxide can be purchased.

Authors’ note – the chemicals required to make a Nembutal may be classified as ‘precursors’ for the synthesis of a restricted substance. Possession of significant quantities of these items may be an indictable offence and could result in significant penalties.

Getting the Equipment Needed to make Nembutal

How to make Nembutal at home: Equipment.

Laboratory glassware is becoming increasingly hard to obtain. This is a reaction on the part of the authorities to the existence of clandestine laboratories that manufacture illegal drugs (predominantly amphetamines) for commercial gain. The award-winning TV series ‘Breaking Bad’ is an excellent example of what can occur in the dark underworld of blackmarket drugs.

Some of the chemical techniques used in the synthesis of a Peaceful Pill are the same as those used to make illicit drugs.

The synthesis in Exit’s projects required a prolonged period of reflux (Fig 20.1).

A glass reaction vessel with 3 Quickfit taper necks (24/29), fitted with an efficient double surface condenser was needed. A heating mantle and a means of stirring the mixture and monitoring the temperature were also used. To protect the reacting substances from atmospheric moisture calcium chloride guard tubes are needed. The double surface condenser can be attached to the reactor vessel by means of a distillation head.

A glass receiving vessel, fitted with a calcium chloride guard tube, is needed to collect the distillate (Fig 20.5).

An accurate chemical balance capable of measuring to 0.1 g is required in order to weigh out the necessary reactants.

Distributors of this specialized glassware (eg. reaction vessels with Quickfit necks, double-surface condensers, distillation heads, guard tubes etc) are often required to inform authorities of ‘suspicious’ purchases. For this reason it can be helpful to know someone who has access to laboratory glassware and glass-blowing skills.

The manufacture of specialised equipment in stainless steel avoids some of these difficulties. The stainless reaction autoclave used in the ‘Single Shot’ process has been adapted from a coffee pot. This method has since been modified as problems with the process were realized. The equipment now used consists of:

- a stainless steel pressure reactor vessel with pressure and temperature monitor and stirring facility

- a stainless condenser used for reflux and solvent extraction

- a stainless receiving container fitted with calcium chloride guard tubes

Stages involved in making Nembutal at home

If you are looking at how to make Nembutal at home then you must follow the below steps;

- Step 1: Attaching the first sidechain to the di-ethyl malonate

- Step 2: Attaching the second sidechain to the product of step 1

- Step 3: Condensing the di-substituted malonate with urea to form the required barbiturate

Looking at these steps in more detail

Step 1

In the case of the target barbiturates, Nembutal or Amytal, the first sidechain to be attached to the di-ethyl malonate is an ethyl halide, usually ethyl bromide is used. To form the mono-sustituted malonic ester, ethyl bromide is heated with the di-ethyl malonate in the presence of the required catalyst – the base, sodium ethoxide.

The catalyst may be purchased or made as part of the process.

To make the required ethoxide add 5.7g of metallic sodium that has been cleaned by passing through a press – see ‘Betty cooks with Sodium’ – and 125ml of very dry alcohol.

Into this mixture of dry alcohol and sodium ethoxide add 38ml of di-ethyl malonate and 26g of bromoethane. Heat is applied and the mixture stirred using a magnetic stirrer. In an open system a reflux condenser must be fitted and a calcium chloride guard tube used to ensure no contamination by atmospheric moisture.

Note: Super Dry Alcohol

Alcohol (ethanol) of the required dryness can be made using methylated spirits as the starting point (95.6% alcohol). Absolute ethanol (>99.5%) is obtained by heating this under reflux with dry (recently fired) calcium oxide. To significantly improve the yield in the synthesis of barbiturates, even dryer alcohol is required. To remove more of the water, thereby converting the 99.5% ethanol to ‘super dry’ alcohol (>99.8%), use 5gm of magnesium turnings with 0.5gm of iodine in a boiling vessel.

Let the magnesium react with ~50ml of the 99.5% ethanol producing hydrogen and magnesium ethanolate. When all of the magnesium has been consumed, the remainder of the absolute alcohol is added, refluxed for 30 minutes, and distilled directly into the planned storage vessel. The resulting ethanol should be better than 99.95%. See the Video Making super dry alcohol’

Step 2

Sodium ethoxide catalyst is again needed in the reaction vessel, and this time 47g of the monosubstituted ester from Step 1 is converted to a di-substituted ester by reflux or reaction in an autoclave) with the second side chain. For the synthesis of Amytal, this second sidechain is 1-bromo-3 methylbutane. In the case of Nembutal, it is 2-bromopentane, in each case 38g is required.

At the end of this stage the di-substituted malonate is removed again by vacuum distillation. This is 3-methyl-butyl-ethyl malonic ester in the case of Amytal synthesis; 1-methyl butyl-ethyl malonic ester if Nembutal is being manufactured.

Step 3

Sodium ethoxide is again needed in the reaction vessel. For this final step 58g of the di-substituted malonate from step 2 is allowed to react with 15g of dry urea that has been dissolved in hot dry alcohol. The mixture is stirred and heated under reflux.

After 4 hours, the excess alcohol is boiled off and the residue dissolved in water and acidified (with dilute hydrochloric acid) to precipitate the insoluble barbiturate crystals which can be washed and dried.

Testing the Product

After making the Nembutal, careful testing is very necessary.

Full reassurance can only come from detailed, quantitative analysis using gas chromatography and mass spectroscopy (GC-MS).

We took possession of this necessary equipment in 2008.

Apart from the ability to test the products of home synthesis, the equipment is useful in verifying the veracity of old stocks of prescribed barbiturate sleeping tablets, or samples of veterinary Nembutal that have been purchased from dubious sources or have long past their quoted shelf life.

Finally, the Barbiturate Test Kit can be used to demonstrate the presence of synthesized barbiturate. In addition, the purity of dried barbiturate crystals can be tested using a glass capillary in an oil bath. For Nembutal, the melting point should be 129°C.

If you need more information on how to make Nembutal at home do not hesitate to contact us.